×

Easy to handle yet strong, ensuring durability and efficiency

Strong thermal insulation and sealing properties for optimal performance

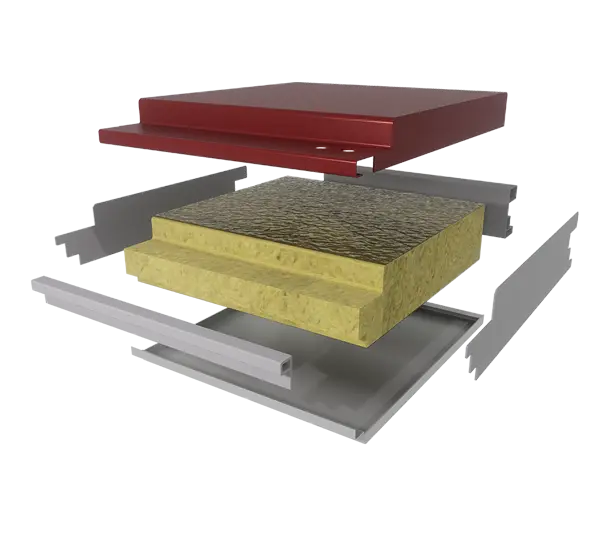

Pre-manufactured for consistent quality, with a splicing and locking mechanism for easy installation

Sleek and modern design that enhances the visual appeal of any building

The choice of panel core significantly impacts a building's performance, but several other key factors also play a crucial role:

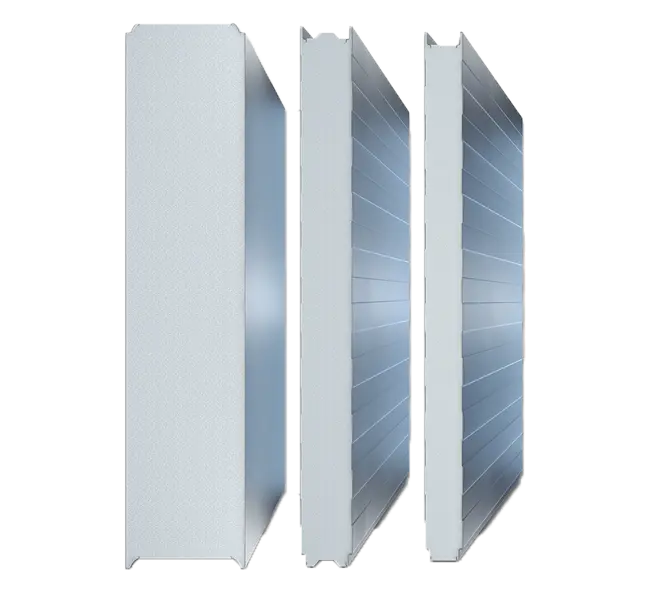

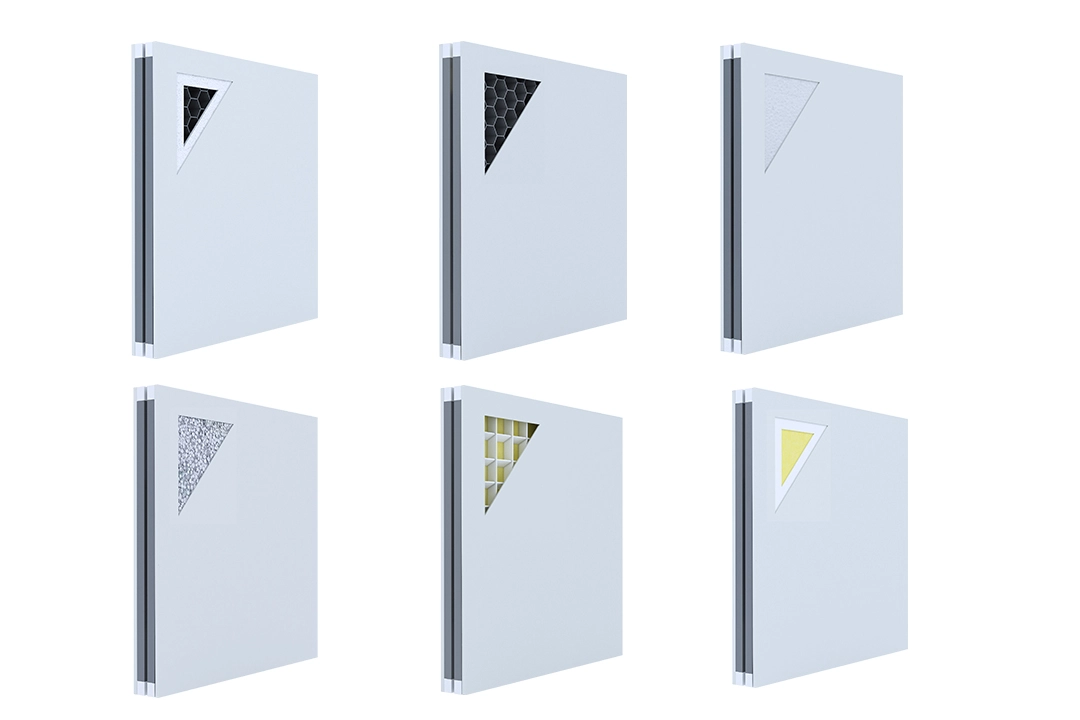

Panel Material: Common options include galvanized steel, stainless steel, and aluminum. Galvanized steel provides excellent corrosion resistance and strength, stainless steel is ideal for environments requiring high hygiene standards, and aluminum is lightweight, making it suitable for specialized applications.

Coating Selection: Different coatings, such as polyester (PE), polyvinylidene fluoride (PVDF), and polyurethane (PU), influence weather resistance, corrosion resistance, and overall aesthetics.

Thickness Parameters: Both the panel and core thickness affect load-bearing capacity, thermal insulation, and soundproofing. The choice should align with the specific project requirements.

Additionally, the installation method impacts construction efficiency and sealing performance. Ultimately, the most suitable solution can be customized based on the project's unique needs and budget.

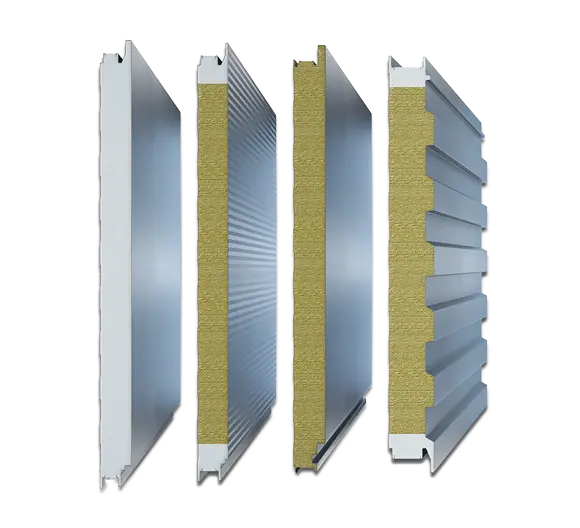

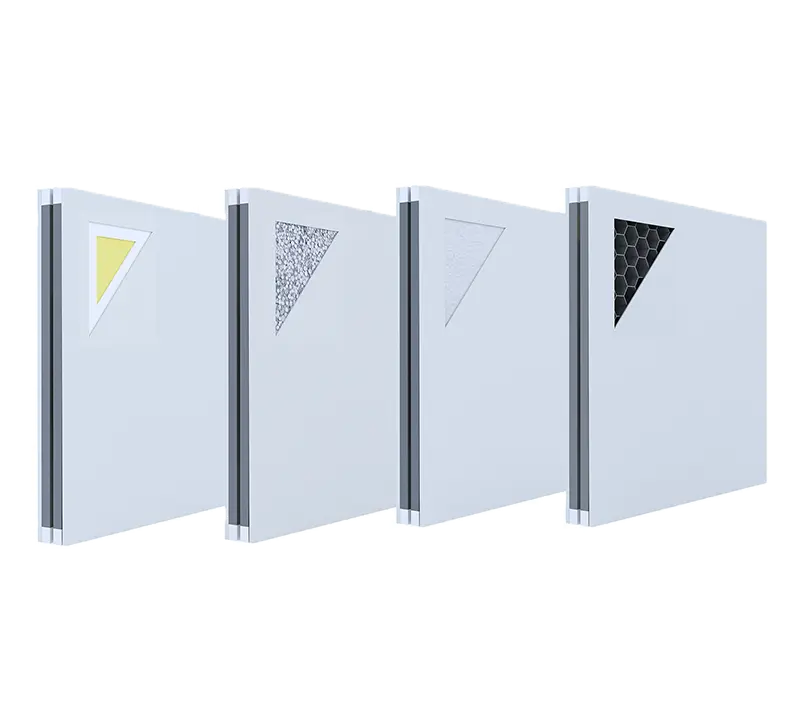

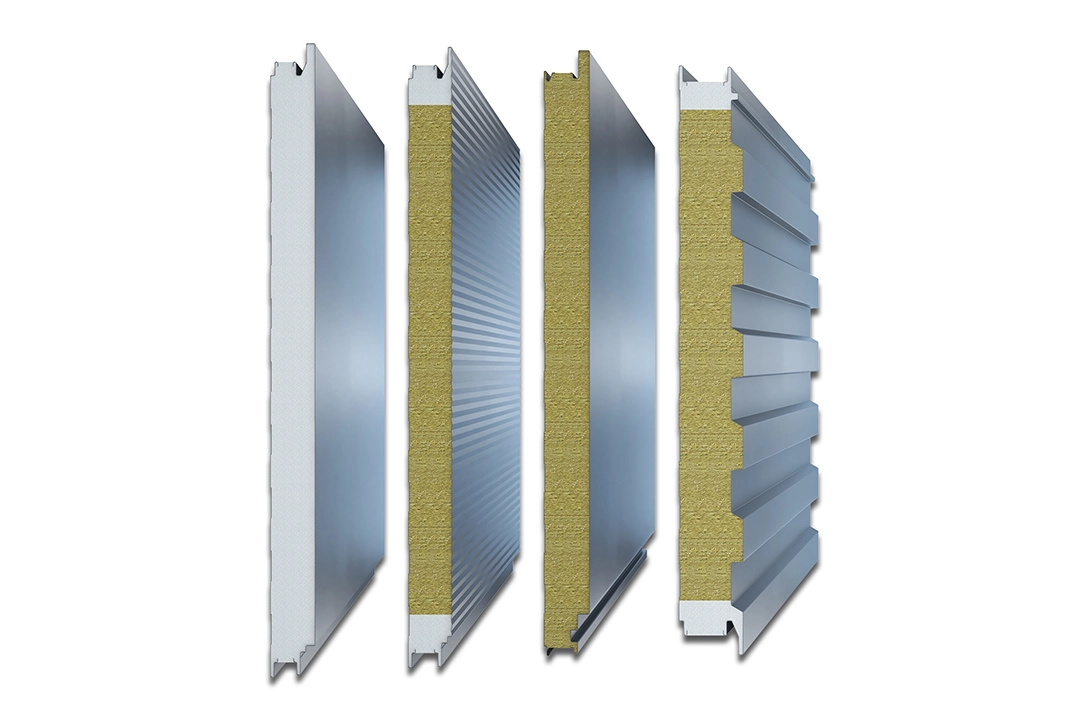

The sandwich panel core material choice significantly impacts insulation, fire resistance, and structural performance. Our panels typically use polyurethane foam, rock wool, or glass wool cores.

Foam Core: Polyurethane (PUR) panels provide high thermal insulation but have limited fire resistance, while polyisocyanurate (PIR) improves fire resistance, thermal stability, and overall performance.

Rock Wool Core: Known for excellent fire resistance and superior acoustic insulation, rock wool panels are heavier and less thermally insulating than PIR.

Glass Wool Core: Offering fire resistance, thermal and acoustic insulation, lightweight installation, and moisture resistance, glass wool panels have lower structural strength and are sensitive to moisture and compression.

The choice of core material depends on the specific building application, and both the core type and thickness can be customized. Based on your needs, we will provide the most suitable and satisfactory recommendations.

This page features the most frequently asked questions and detailed answers. You can find comprehensive information here or submit your inquiries. If you need assistance with ordering panels or have technical questions, feel free to contact us.

The cost of sandwich panels varies based on several factors, including the type of insulation, panel thickness, and total square footage required. Pricing is flexible and can be tailored to your project needs. For an accurate quote, please contact our team with your specifications.

Our sandwich panels feature high-quality galvanized or galvalume metal sheets with a lightweight, insulating core for superior durability and thermal performance.

Our sandwich panels are available in widths of 400mm–1200mm, and thicknesses of 40mm–200mm, with customizable lengths, and we offer tailored solutions to meet your needs.

Service life at the correct operation is 50 years. We are providing a written guarantee.

Guaranteed production time from 5 to 10 working days. Sometimes it is possible to manufacture for up to only 3 days. Contact us for more details. But if you need a non-standard color or metal thickness, the production time may increase to 20 days.

Welcome to contact us for anything you want to know.